Global Alloy Market Overview:

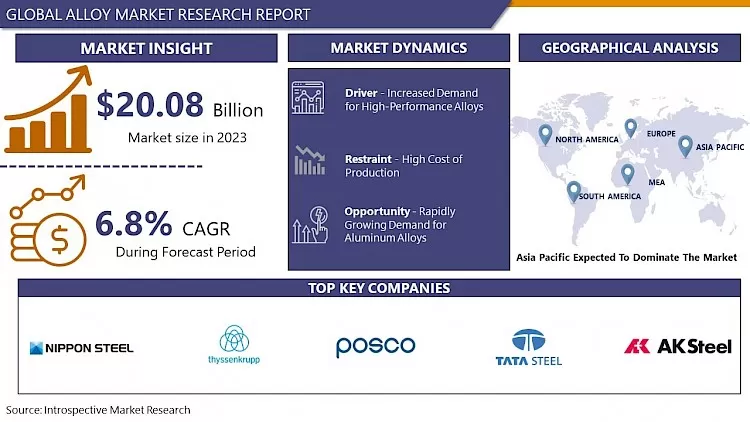

Global Alloy Market size was valued at USD 20.08 billion in 2023 and is projected to reach USD 36.3 billion by 2032, growing at a CAGR of 6.8% from 2024 to 2032.

- The global alloy market is a dynamic and critical segment of the metals industry, playing a role in various sectors such as aerospace, automotive, construction, and manufacturing. Alloys are materials composed of two or more metallic elements or a combination of metals and non-metals, engineered to possess specific properties and characteristics that are superior to individual metals. The market is characterized by its substantial growth and diversification over the years, driven by technological advancements and the increasing demand for high-performance materials.

- The global alloy market's growth is its extensive use in the automotive and aerospace industries. Alloys like aluminum alloys, stainless steel, and titanium alloys are essential components in the production of lightweight and durable automotive and aircraft parts, contributing to fuel efficiency and improved performance. The rising need for energy-efficient and eco-friendly transportation options has further spurred the demand for innovative alloy materials in this sector.

- Alloys are also indispensable in the construction and infrastructure sectors. High-strength alloys are employed in structural components, ensuring the stability and safety of buildings, bridges, and other infrastructure projects. The market for corrosion-resistant alloys has also witnessed significant growth due to the need for long-lasting and low-maintenance structures in various environments.

Alloy Market Trend Analysis

Increased Demand for High-Performance Alloys

- The increased demand for high-performance alloys in the Alloy Market can be attributed to several key factors driving growth and transformation in various industries. Firstly, advancements in technology have spurred the demand for materials that can withstand extreme conditions and deliver superior performance. High-performance alloys, known for their exceptional mechanical properties and resistance to corrosion and heat, have become crucial in applications ranging from aerospace and automotive to energy production and medical devices.

- The growing emphasis on sustainability and environmental concerns has prompted industries to seek more durable and longer-lasting materials. High-performance alloys not only extend the lifespan of components but also reduce the need for frequent replacements and repairs, ultimately minimizing waste and resource consumption. This eco-friendly aspect of high-performance alloys aligns with the global push toward sustainable practices and circular economies.

- Aerospace and automotive sectors have witnessed a surge in demand for lightweight materials that can enhance fuel efficiency and reduce emissions. High-performance alloys offer a compelling solution, as they provide the desired strength-to-weight ratio, enabling manufacturers to create lighter yet robust components. As the world moves towards stricter emission regulations and greater energy efficiency, high-performance alloys are likely to play a pivotal role in achieving these goals.

Rapidly Growing Demand for Aluminum Alloys

- The automotive industry has been a major driver of increased demand for aluminum alloys. Aluminum is lightweight, corrosion-resistant, and offers an excellent strength-to-weight ratio, making it an ideal choice for manufacturers aiming to reduce the overall weight of vehicles. As automotive manufacturers prioritize fuel efficiency and emissions reduction, aluminum alloys have become a preferred material for components like body panels, engine blocks, and suspension parts. The shift towards electric vehicles (EVs) further amplifies this demand, as aluminum's lightweight properties contribute to extending the range of EVs.

- Aerospace industry has also witnessed a surge in the use of aluminum alloys. With air travel on the rise, aircraft manufacturers are constantly seeking materials that provide durability while minimizing weight. Aluminum alloys meet these criteria, making them integral in the construction of various aircraft components, such as fuselages, wings, and landing gear. Moreover, the aerospace industry's drive towards fuel efficiency has led to the development of more advanced aluminum alloys that offer enhanced performance characteristics, further boosting their demand.

- The construction and building sectors have contributed significantly to the increased demand for aluminum alloys. Aluminium’s corrosion resistance and strength make it an attractive choice for building facades, structural elements, and interior design applications. The construction industry's emphasis on sustainability has also driven the use of aluminum alloys, as they are highly recyclable, promoting environmentally friendly practices.

Segmentation Analysis of The Alloy Market

Alloy Market segments cover the type of alloy, material type, vehicle type, and end-user industry. By Material Type, the Aluminium Alloy segment is Anticipated to Dominate the Market Over the Forecast period.

- Aluminum Alloys are highly regarded for their lightweight yet durable characteristics. This unique blend of strength and low density makes them ideal for applications where weight reduction is critical, such as in the automotive and aerospace industries. The lightweight nature of aluminum alloys can lead to improved fuel efficiency in vehicles and increased payload capacity in aircraft, which are essential considerations in today's environmentally conscious and cost-sensitive markets.

- The recycling process requires significantly less energy compared to primary production, contributing to reduced greenhouse gas emissions. This sustainability aspect is becoming increasingly important as environmental concerns grow, and industries strive to meet stricter regulations and consumer demands for greener products. The recyclability of aluminum alloys further solidifies their dominance in the market as a sustainable choice.

- Aluminum alloys possess excellent thermal and electrical conductivity properties. These qualities make them valuable in various applications, such as electrical wiring, heat exchangers, and electronic components. The versatility of aluminum alloys across multiple industries, from automotive to electronics, ensures a steady demand, further strengthening their position as a dominant material type in the market.

Regional Analysis of The Alloy Market

Asia Pacific is Expected to Dominate the Market Over the Forecast Period.

- The Asia Pacific region is poised to become the largest market for alloys, commanding the automotive sector in the Asia Pacific region has experienced substantial growth in recent years. This can be attributed to the rising middle-class population and increasing urbanization, which have led to greater demand for automobiles. Alloys play a pivotal role in automotive manufacturing, as they offer superior strength, lightweight properties, and resistance to corrosion. As automakers in the Asia Pacific region strive to meet these demands, the demand for alloys has surged, driving the market's growth.

- Industry in the Asia Pacific region is on an upward trajectory. This is driven by both domestic and international factors. Many Asian countries have been investing heavily in the development of their aerospace capabilities, leading to an increased demand for high-performance alloys used in aircraft construction. Furthermore, the region's strategic location makes it a hub for international aerospace manufacturers, which further fuels the demand for alloys.

- In Asia Pacific region has been experiencing a construction boom. Rapid urbanization and infrastructure development projects have spurred the demand for alloys, which are vital components in construction materials, including steel structures and reinforced concrete. As the region continues to invest in building modern cities and infrastructure networks, the consumption of alloys in construction will likely continue to rise.

COVID-19 Impact Analysis on Alloy Market

The COVID-19 pandemic had a significant impact on the global alloy market. During the initial phases of the pandemic, widespread lockdowns and disruptions in supply chains led to a sharp decline in demand for alloys, particularly in industries such as automotive, aerospace, and construction. However, as the world adapted to the new normal and economic activities gradually resumed, the alloy market began to recover, driven by increased demand for medical equipment, electronics, and renewable energy technologies. The pandemic also highlighted the importance of supply chain resilience, leading to efforts to diversify sources and secure raw materials for alloy production. Overall, while COVID-19 posed initial challenges, the alloy market demonstrated resilience and adaptability in responding to the crisis.

Top Key Players Covered in The Alloy Market

Thyssenkrupp AG, POSCO, Tata Steel, AK Steel Holding Corporation, Allegheny Technologies, Incorporated (ATI), Carpenter Technology Corporation, Kobe Steel Ltd., JFE Steel Corporation, Aperam, Sandvik AB, Carpenter Technology Corporation, Timkensteel Corporation, Haynes International, Nucor Corporation, VSMPO-AVISMA Corporation, Ulbrich Stainless Steels & Special Metals, Special Metals Corporation, Voestalpine AG, Mukand Limited, AMETEK Specialty Metal Products, Precision Castparts Corp (PCC), Allegheny Ludlum and Other Major Players.

Key Industry Developments in the Alloy Market

- In April 2024, the acquisition of United States Steel by Nippon Steel was approved by U.S. Steel’s stockholders at a special meeting of stockholders held on April 12, 2024 (local time). Nippon Steel expressed confidence that the acquisition would protect and grow U.S. Steel and bring significant benefits to its stakeholders, including customers, employees, union workers, suppliers, communities, and stockholders – as well as to the American steel industry and the United States as a whole. The vote yesterday represented a major step toward achieving this goal.

- In April 2024, thyssenkrupp AG and EP Corporate Group a.s. (EPCG) agreed on EPCG’s acquisition of a stake in thyssenkrupp's steel business. EPCG acquired 20 percent of thyssenkrupp’s steel business, with the parties opting not to disclose the valuation of the transaction. The transaction was anticipated to close in the current fiscal year of thyssenkrupp AG, pending approval from the relevant authorities and thyssenkrupp AG's Supervisory Board. Additionally, discussions were underway regarding EPCG's potential acquisition of a further 30 percent stake in the steel business, with the aim of establishing a 50/50 joint venture.

|

Alloy Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 20.08 Bn. |

|

Forecast Period 2024-32 CAGR: |

6.8% |

Market Size in 2032: |

USD 36.3 Bn. |

|

Segments Covered: |

By Type of Alloy |

|

|

|

By Material Type |

|

||

|

By Vehicle Type |

|

||

|

By End-Use Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the Report: |

|

||

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Alloy Market by By Type of Alloy (2018-2032)

4.1 Alloy Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Ferrous Alloys

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Non-Ferrous Alloys

4.5 Superalloys

4.6 Noble Alloys

Chapter 5: Alloy Market by By Material Type (2018-2032)

5.1 Alloy Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Aluminum Alloy

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Titanium Alloy

5.5 Magnesium Alloy

Chapter 6: Alloy Market by By Vehicle Type (2018-2032)

6.1 Alloy Market Snapshot and Growth Engine

6.2 Market Overview

6.3 Passenger Vehicles

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

6.3.3 Key Market Trends, Growth Factors, and Opportunities

6.3.4 Geographic Segmentation Analysis

6.4 Commercial Vehicles

Chapter 7: Alloy Market by By End-Use Industry (2018-2032)

7.1 Alloy Market Snapshot and Growth Engine

7.2 Market Overview

7.3 Automotive

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

7.3.3 Key Market Trends, Growth Factors, and Opportunities

7.3.4 Geographic Segmentation Analysis

7.4 Aerospace and Défense

7.5 Construction

7.6 Electronics

7.7 Oil and Gas

Chapter 8: Company Profiles and Competitive Analysis

8.1 Competitive Landscape

8.1.1 Competitive Benchmarking

8.1.2 Alloy Market Share by Manufacturer (2024)

8.1.3 Industry BCG Matrix

8.1.4 Heat Map Analysis

8.1.5 Mergers and Acquisitions

8.2 UPS SUPPLY CHAIN SOLUTIONS (US)

8.2.1 Company Overview

8.2.2 Key Executives

8.2.3 Company Snapshot

8.2.4 Role of the Company in the Market

8.2.5 Sustainability and Social Responsibility

8.2.6 Operating Business Segments

8.2.7 Product Portfolio

8.2.8 Business Performance

8.2.9 Key Strategic Moves and Recent Developments

8.2.10 SWOT Analysis

8.3 PENSKE LOGISTICS (US)

8.4 XPO LOGISTICS (US)

8.5 FEDEX SUPPLY CHAIN (US)

8.6 C.H. ROBINSON (US)

8.7 EXPEDITORS INTERNATIONAL (US)

8.8 ARCBEST CORPORATION (US)

8.9 RYDER SYSTEM (US)

8.10 DHL SUPPLY CHAIN (GERMANY)

8.11 DB SCHENKER (GERMANY)

8.12 DACHSER (GERMANY)

8.13 HELLMANN WORLDWIDE LOGISTICS (GERMANY)

8.14 BOLLORE LOGISTICS (FRANCE)

8.15 GEODIS (FRANCE)

8.16 SNCF LOGISTICS (FRANCE)

8.17 CEVA LOGISTICS (SWITZERLAND)

8.18 NIPPON EXPRESS (JAPAN)

8.19 KINTETSU WORLD EXPRESS (JAPAN)

8.20 HITACHI TRANSPORT SYSTEM (JAPAN)

8.21 YUSEN LOGISTICS (JAPAN)

8.22 KWE KINTETSU WORLD EXPRESS (JAPAN)

8.23 AGILITY LOGISTICS (KUWAIT)

8.24

Chapter 9: Global Alloy Market By Region

9.1 Overview

9.2. North America Alloy Market

9.2.1 Key Market Trends, Growth Factors and Opportunities

9.2.2 Top Key Companies

9.2.3 Historic and Forecasted Market Size by Segments

9.2.4 Historic and Forecasted Market Size By By Type of Alloy

9.2.4.1 Ferrous Alloys

9.2.4.2 Non-Ferrous Alloys

9.2.4.3 Superalloys

9.2.4.4 Noble Alloys

9.2.5 Historic and Forecasted Market Size By By Material Type

9.2.5.1 Aluminum Alloy

9.2.5.2 Titanium Alloy

9.2.5.3 Magnesium Alloy

9.2.6 Historic and Forecasted Market Size By By Vehicle Type

9.2.6.1 Passenger Vehicles

9.2.6.2 Commercial Vehicles

9.2.7 Historic and Forecasted Market Size By By End-Use Industry

9.2.7.1 Automotive

9.2.7.2 Aerospace and Défense

9.2.7.3 Construction

9.2.7.4 Electronics

9.2.7.5 Oil and Gas

9.2.8 Historic and Forecast Market Size by Country

9.2.8.1 US

9.2.8.2 Canada

9.2.8.3 Mexico

9.3. Eastern Europe Alloy Market

9.3.1 Key Market Trends, Growth Factors and Opportunities

9.3.2 Top Key Companies

9.3.3 Historic and Forecasted Market Size by Segments

9.3.4 Historic and Forecasted Market Size By By Type of Alloy

9.3.4.1 Ferrous Alloys

9.3.4.2 Non-Ferrous Alloys

9.3.4.3 Superalloys

9.3.4.4 Noble Alloys

9.3.5 Historic and Forecasted Market Size By By Material Type

9.3.5.1 Aluminum Alloy

9.3.5.2 Titanium Alloy

9.3.5.3 Magnesium Alloy

9.3.6 Historic and Forecasted Market Size By By Vehicle Type

9.3.6.1 Passenger Vehicles

9.3.6.2 Commercial Vehicles

9.3.7 Historic and Forecasted Market Size By By End-Use Industry

9.3.7.1 Automotive

9.3.7.2 Aerospace and Défense

9.3.7.3 Construction

9.3.7.4 Electronics

9.3.7.5 Oil and Gas

9.3.8 Historic and Forecast Market Size by Country

9.3.8.1 Russia

9.3.8.2 Bulgaria

9.3.8.3 The Czech Republic

9.3.8.4 Hungary

9.3.8.5 Poland

9.3.8.6 Romania

9.3.8.7 Rest of Eastern Europe

9.4. Western Europe Alloy Market

9.4.1 Key Market Trends, Growth Factors and Opportunities

9.4.2 Top Key Companies

9.4.3 Historic and Forecasted Market Size by Segments

9.4.4 Historic and Forecasted Market Size By By Type of Alloy

9.4.4.1 Ferrous Alloys

9.4.4.2 Non-Ferrous Alloys

9.4.4.3 Superalloys

9.4.4.4 Noble Alloys

9.4.5 Historic and Forecasted Market Size By By Material Type

9.4.5.1 Aluminum Alloy

9.4.5.2 Titanium Alloy

9.4.5.3 Magnesium Alloy

9.4.6 Historic and Forecasted Market Size By By Vehicle Type

9.4.6.1 Passenger Vehicles

9.4.6.2 Commercial Vehicles

9.4.7 Historic and Forecasted Market Size By By End-Use Industry

9.4.7.1 Automotive

9.4.7.2 Aerospace and Défense

9.4.7.3 Construction

9.4.7.4 Electronics

9.4.7.5 Oil and Gas

9.4.8 Historic and Forecast Market Size by Country

9.4.8.1 Germany

9.4.8.2 UK

9.4.8.3 France

9.4.8.4 The Netherlands

9.4.8.5 Italy

9.4.8.6 Spain

9.4.8.7 Rest of Western Europe

9.5. Asia Pacific Alloy Market

9.5.1 Key Market Trends, Growth Factors and Opportunities

9.5.2 Top Key Companies

9.5.3 Historic and Forecasted Market Size by Segments

9.5.4 Historic and Forecasted Market Size By By Type of Alloy

9.5.4.1 Ferrous Alloys

9.5.4.2 Non-Ferrous Alloys

9.5.4.3 Superalloys

9.5.4.4 Noble Alloys

9.5.5 Historic and Forecasted Market Size By By Material Type

9.5.5.1 Aluminum Alloy

9.5.5.2 Titanium Alloy

9.5.5.3 Magnesium Alloy

9.5.6 Historic and Forecasted Market Size By By Vehicle Type

9.5.6.1 Passenger Vehicles

9.5.6.2 Commercial Vehicles

9.5.7 Historic and Forecasted Market Size By By End-Use Industry

9.5.7.1 Automotive

9.5.7.2 Aerospace and Défense

9.5.7.3 Construction

9.5.7.4 Electronics

9.5.7.5 Oil and Gas

9.5.8 Historic and Forecast Market Size by Country

9.5.8.1 China

9.5.8.2 India

9.5.8.3 Japan

9.5.8.4 South Korea

9.5.8.5 Malaysia

9.5.8.6 Thailand

9.5.8.7 Vietnam

9.5.8.8 The Philippines

9.5.8.9 Australia

9.5.8.10 New Zealand

9.5.8.11 Rest of APAC

9.6. Middle East & Africa Alloy Market

9.6.1 Key Market Trends, Growth Factors and Opportunities

9.6.2 Top Key Companies

9.6.3 Historic and Forecasted Market Size by Segments

9.6.4 Historic and Forecasted Market Size By By Type of Alloy

9.6.4.1 Ferrous Alloys

9.6.4.2 Non-Ferrous Alloys

9.6.4.3 Superalloys

9.6.4.4 Noble Alloys

9.6.5 Historic and Forecasted Market Size By By Material Type

9.6.5.1 Aluminum Alloy

9.6.5.2 Titanium Alloy

9.6.5.3 Magnesium Alloy

9.6.6 Historic and Forecasted Market Size By By Vehicle Type

9.6.6.1 Passenger Vehicles

9.6.6.2 Commercial Vehicles

9.6.7 Historic and Forecasted Market Size By By End-Use Industry

9.6.7.1 Automotive

9.6.7.2 Aerospace and Défense

9.6.7.3 Construction

9.6.7.4 Electronics

9.6.7.5 Oil and Gas

9.6.8 Historic and Forecast Market Size by Country

9.6.8.1 Turkiye

9.6.8.2 Bahrain

9.6.8.3 Kuwait

9.6.8.4 Saudi Arabia

9.6.8.5 Qatar

9.6.8.6 UAE

9.6.8.7 Israel

9.6.8.8 South Africa

9.7. South America Alloy Market

9.7.1 Key Market Trends, Growth Factors and Opportunities

9.7.2 Top Key Companies

9.7.3 Historic and Forecasted Market Size by Segments

9.7.4 Historic and Forecasted Market Size By By Type of Alloy

9.7.4.1 Ferrous Alloys

9.7.4.2 Non-Ferrous Alloys

9.7.4.3 Superalloys

9.7.4.4 Noble Alloys

9.7.5 Historic and Forecasted Market Size By By Material Type

9.7.5.1 Aluminum Alloy

9.7.5.2 Titanium Alloy

9.7.5.3 Magnesium Alloy

9.7.6 Historic and Forecasted Market Size By By Vehicle Type

9.7.6.1 Passenger Vehicles

9.7.6.2 Commercial Vehicles

9.7.7 Historic and Forecasted Market Size By By End-Use Industry

9.7.7.1 Automotive

9.7.7.2 Aerospace and Défense

9.7.7.3 Construction

9.7.7.4 Electronics

9.7.7.5 Oil and Gas

9.7.8 Historic and Forecast Market Size by Country

9.7.8.1 Brazil

9.7.8.2 Argentina

9.7.8.3 Rest of SA

Chapter 10 Analyst Viewpoint and Conclusion

10.1 Recommendations and Concluding Analysis

10.2 Potential Market Strategies

Chapter 11 Research Methodology

11.1 Research Process

11.2 Primary Research

11.3 Secondary Research

|

Alloy Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 20.08 Bn. |

|

Forecast Period 2024-32 CAGR: |

6.8% |

Market Size in 2032: |

USD 36.3 Bn. |

|

Segments Covered: |

By Type of Alloy |

|

|

|

By Material Type |

|

||

|

By Vehicle Type |

|

||

|

By End-Use Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the Report: |

|

||

Frequently Asked Questions :

The forecast period in the Alloy Market research report is 2024-2032.

Nippon Steel Corporation, POSCO, Thyssenkrupp AG, Tata Steel, AK Steel Holding Corporation, Allegheny Technologies, Incorporated (ATI), Carpenter Technology Corporation, Kobe Steel Ltd., JFE Steel Corporation, Aperam, Sandvik AB, Carpenter Technology Corporation, Timkensteel Corporation, Haynes International, Nucor Corporation, VSMPO-AVISMA Corporation, Ulbrich Stainless Steels & Special Metals, Special Metals Corporation, Voestalpine AG, Mukand Limited, AMETEK Specialty Metal Products, Precision Castparts Corp (PCC), Allegheny Ludlum and Other Major Players.

The Alloy Market is segmented into Type of Alloy, Material Type, Vehicle Type, End-Use Industry, and region. By Type of Alloy, the market is categorized into Ferrous Alloys, Non-Ferrous Alloys, Superalloys, and Noble Alloys. Material Type, the market is categorized into Aluminium Alloy, Titanium Alloy, and Magnesium Alloy. By Vehicle Type, the market is categorized into Passenger Vehicles and Commercial Vehicles. By End-Use Industry, the market is categorized into Automotive, Aerospace and Defense, Construction, Electronics, Oil and Gas. By region, it is analyzed across North America (U.S.; Canada; Mexico), Europe (Germany; U.K.; France; Italy; Russia; Spain, etc.), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

The global alloy market is a dynamic and critical segment of the metals industry, playing a role in various sectors such as aerospace, automotive, construction, and manufacturing. Alloys are materials composed of two or more metallic elements or a combination of metals and non-metals, engineered to possess specific properties and characteristics that are superior to individual metals. This market is characterized by its substantial growth and diversification over the years, driven by technological advancements and the increasing demand for high-performance materials.

Global Alloy Market size was valued at USD 20.08 billion in 2023 and is projected to reach USD 36.3 billion by 2032, growing at a CAGR of 6.8% from 2024 to 2032.