Global Basalt Fiber Sleeve Market Overview

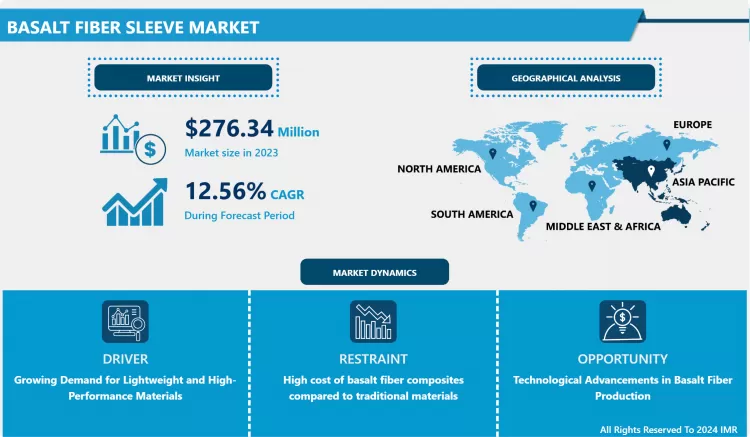

Basalt Fiber Sleeve Market Size Was Valued at USD 276.34 Million in 2023 and is Projected to Reach USD 801.49 Million by 2032, Growing at a CAGR of 12.56% From 2024-2032.

-

A basalt fiber sleeve is a tubular structure crafted from basalt fibers, extracted from natural volcanic rock. These fibers, created by melting basalt at high temperatures and extruding the material, boast remarkable strength, heat resistance, durability, and corrosion resilience. Basalt fiber sleeves are versatile components prized for their multifunctional roles in various industries. They excel in diverse applications owing to their exceptional characteristics. Functioning as high-performance solutions, these sleeves address specific industry needs.

-

Primarily, they serve as robust thermal insulators in settings where extreme heat is prevalent, including automotive engines, industrial machinery, and pipelines. Their ability to prevent heat transfer is crucial for maintaining operational efficiency in such environments. Additionally, these sleeves offer substantial mechanical protection, shielding cables, hoses, and pipes from harsh conditions such as abrasion, wear, and exposure to chemicals. Moreover, when used as reinforcement in composite materials, they significantly enhance the structural integrity of various items like composite pipes, tanks, and construction materials.

-

These sleeves boast a range of benefits, including high-temperature resistance, ensuring they retain their structure even in extreme heat. Their exceptional tensile strength guarantees durability under mechanical stress, while their resistance to corrosion and various chemicals ensures reliability in harsh conditions. Furthermore, their lightweight and flexible nature facilitates easy installation and adaptation to diverse shapes and sizes. Derived from natural volcanic rock, basalt fibers also present an environmentally friendly alternative and find extensive applications across aerospace, automotive, construction, marine, and other industries.

Basalt Fiber Sleeve Market Trend Analysis:

Growing Demand for Lightweight And High-Performance Materials

-

The global Basalt Fiber Sleeve market has seen a notable surge owing to rising demand for lightweight, high-performance materials in industries like aerospace, automotive, construction, and electronics. Basalt Fiber Sleeves, sourced from natural volcanic rock, boast exceptional qualities such as strength, durability, and resistance to extreme conditions like high temperatures, corrosion, and chemicals. This makes them highly desirable for various applications.

-

An essential driving force behind this market's growth is the increasing need for lightweight materials that retain robust structural integrity. Industries such as aerospace and automotive are actively seeking lighter alternatives to boost fuel efficiency, reduce emissions, and enhance overall performance. Basalt Fiber Sleeves, with their impressive strength-to-weight ratios, offer an ideal solution by enabling the production of lightweight components without compromising durability.

-

Additionally, the growing focus on sustainability and environmental concerns further amplifies the demand for basalt-based materials. Being eco-friendly and derived from naturally occurring basalt rock, these sleeves are preferred over traditional materials like fiberglass due to their lower environmental impact and recyclability. This rising trend aligns with industries' increasing prioritization of eco-conscious materials in their manufacturing processes, contributing to the expanding global prominence of the Basalt Fiber Sleeve market.

Technological Advancements in Basalt Fiber Production

-

Advancements in basalt fiber production represent a significant opportunity for the Global Basalt Fiber Sleeve Market. Continuous innovations in manufacturing processes have resulted in improved quality, efficiency, and cost-effectiveness, leading to broader acceptance and utilization of basalt-based materials across diverse industries. These advancements have driven refinements in basalt fiber production techniques, enabling the creation of superior material properties and expanding potential applications.

-

The refinement of production methods now allows for the customization of basalt fibers, enabling manufacturers to tailor Basalt Fiber Sleeves to specific industry requirements by adjusting characteristics such as diameters, lengths, and strengths. This customization ability empowers these sleeves to cater to a wide range of applications. Moreover, improvements in the prevalent melt-spinning process used in basalt fiber production have increased production rates and elevated fiber quality, thereby enhancing the scalability of manufacturing operations.

-

Furthermore, ongoing research and development initiatives aimed at exploring new composite materials and enhancing basalt fiber properties offer promising prospects for market growth. Innovations in areas like resin compatibility, surface treatments, and composite formulations have the potential to broaden the application scope of Basalt Fiber Sleeves, fostering their adoption in industries like automotive, aerospace, marine, and infrastructure. These developments underscore the significant potential for the Basalt Fiber Sleeve Market's expansion through technological advancements in basalt fiber production.

Basalt Fiber Sleeve Market Segment Analysis:

Basalt Fiber Sleeve Market Segmented on the basis of type, and application

By Type, Maximum Continuous Temp: 700°C dominates the global basalt fiber sleeve market during the forecast period

-

The segment featuring basalt fiber sleeves with a maximum continuous temperature of 700°C holds a prominent position in the global market due to its exceptional heat-resistant properties. Widely utilized across industries like aerospace, automotive, metallurgy, and petrochemicals, these sleeves act as protective covers for components in high-temperature environments, ensuring insulation and preventing thermal damage. Their ability to endure extreme temperatures while maintaining structural integrity and mechanical properties makes them indispensable for applications requiring thermal insulation and protection against hot gases and molten metals. Continuous advancements aimed at enhancing basalt fiber's thermal resistance further bolster the segment's dominance, meeting industries' needs for materials that withstand higher temperatures while delivering stability and performance.

Basalt Fiber Sleeve Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast period

-

The dominance of Asia-Pacific in the global basalt fiber sleeve market stems from several key factors. Primarily, the region's rapid industrialization and burgeoning infrastructure projects create substantial demand for high-performance materials like basalt fiber sleeves. Countries such as China, India, Japan, and South Korea are heavily investing in sectors like aerospace, automotive, construction, and manufacturing, where these sleeves serve diverse applications.

-

Moreover, Asia-Pacific's robust manufacturing sector, particularly in automotive and electronics, significantly drives the utilization of basalt fiber sleeves for thermal insulation and component protection. The increased adoption of advanced technologies and a growing emphasis on energy efficiency and sustainability further propel the demand for basalt fiber materials in the region. Additionally, the availability of raw materials and cost-effective production capabilities within Asia-Pacific countries plays a pivotal role in market expansion. Local manufacturers benefit from easier access to basalt resources and streamlined production processes, enabling them to offer competitive pricing and a wide range of basalt fiber sleeve products.

-

Furthermore, supportive government initiatives promoting infrastructure development and fostering technological advancements in emerging economies within the region contribute significantly to Asia-Pacific's dominance in the global basalt fiber sleeve market. The combined effect of industrial expansion, technological innovations, resource accessibility, and favorable governmental policies solidifies Asia-Pacific's leading position in this market.

Key Players Covered in Basalt Fiber Sleeve Market:

-

Refractory Specialties (USA)

-

Morgan Advanced Materials (USA)

-

HarbisonWalker International (USA)

-

Pyrotek (USA)

-

Owens Corning (USA)

-

Unifrax (USA)

-

Harwick Group (USA)

-

Thermal Ceramics (USA)

-

Guardian Industries (USA)

-

JCP Minerals (USA)

-

3M (USA)

-

BASF SE (Germany)

-

Knauf Insulation (Germany)

-

Schundler Group (Germany)

-

Technobasalt Invest (Ukraine)

-

Imerys (France)

-

Favier Group (France)

-

Saint-Gobain (France)

-

Rockwool (Denmark)

-

Aerospace Tuoxin (China)

-

Jiangsu Tianlong (China)

-

Toray Industries (Japan)

-

Basalt Fiber India (India)

-

Lotte Chemical (South Korea), and other Major Players

|

Global Basalt Fiber Sleeve Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 276.34 Mn. |

|

Forecast Period 2024-32 CAGR: |

12.56% |

Market Size in 2032: |

USD 801.49 Mn . |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Basalt Fiber Sleeve Market by By Type (2018-2032)

4.1 Basalt Fiber Sleeve Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Maximum Continuous Temp: 649°C

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Maximum Continuous Temp: 700°C

4.5 Maximum Continuous Temp: 800°C

4.6 Others

Chapter 5: Basalt Fiber Sleeve Market by By Application (2018-2032)

5.1 Basalt Fiber Sleeve Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Household Electrical Appliances

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Fluid Transportation Piping’s

5.5 Chemical Industry

5.6 Auto Industry

5.7 Metallurgy

5.8 Others

Chapter 6: Company Profiles and Competitive Analysis

6.1 Competitive Landscape

6.1.1 Competitive Benchmarking

6.1.2 Basalt Fiber Sleeve Market Share by Manufacturer (2024)

6.1.3 Industry BCG Matrix

6.1.4 Heat Map Analysis

6.1.5 Mergers and Acquisitions

6.2 BORGWARNER INC. (U.S.)

6.2.1 Company Overview

6.2.2 Key Executives

6.2.3 Company Snapshot

6.2.4 Role of the Company in the Market

6.2.5 Sustainability and Social Responsibility

6.2.6 Operating Business Segments

6.2.7 Product Portfolio

6.2.8 Business Performance

6.2.9 Key Strategic Moves and Recent Developments

6.2.10 SWOT Analysis

6.3 HORTON HOLDING INC. (U.S.)

6.4 US MOTOR WORKS

6.5 LLC (U.S.)

6.6 HAYDEN AUTOMOTIVE (U.S.)

6.7 DERALE PERFORMANCE (U.S.)

6.8 DORMAN PRODUCTS INC. (U.S.)

6.9 MISHIMOTO AUTOMOTIVE (U.S.)

6.10 FLEX-A-FIT (U.S.)

6.11 GMB NORTH AMERICA INC. (U.S.)

6.12 DAYCO INCORPORATED (U.S.)

6.13 MAHLE GMBH (GERMANY)

6.14 VALEO GROUP (FRANCE)

6.15 EATON (IRELAND)

6.16 MULTI-WING GROUP A/S (DENMARK)

6.17 NISSENS AUTOMOTIVE A/S (DENMARK)

6.18 AISIN CORPORATION (JAPAN)

6.19

Chapter 7: Global Basalt Fiber Sleeve Market By Region

7.1 Overview

7.2. North America Basalt Fiber Sleeve Market

7.2.1 Key Market Trends, Growth Factors and Opportunities

7.2.2 Top Key Companies

7.2.3 Historic and Forecasted Market Size by Segments

7.2.4 Historic and Forecasted Market Size By By Type

7.2.4.1 Maximum Continuous Temp: 649°C

7.2.4.2 Maximum Continuous Temp: 700°C

7.2.4.3 Maximum Continuous Temp: 800°C

7.2.4.4 Others

7.2.5 Historic and Forecasted Market Size By By Application

7.2.5.1 Household Electrical Appliances

7.2.5.2 Fluid Transportation Piping’s

7.2.5.3 Chemical Industry

7.2.5.4 Auto Industry

7.2.5.5 Metallurgy

7.2.5.6 Others

7.2.6 Historic and Forecast Market Size by Country

7.2.6.1 US

7.2.6.2 Canada

7.2.6.3 Mexico

7.3. Eastern Europe Basalt Fiber Sleeve Market

7.3.1 Key Market Trends, Growth Factors and Opportunities

7.3.2 Top Key Companies

7.3.3 Historic and Forecasted Market Size by Segments

7.3.4 Historic and Forecasted Market Size By By Type

7.3.4.1 Maximum Continuous Temp: 649°C

7.3.4.2 Maximum Continuous Temp: 700°C

7.3.4.3 Maximum Continuous Temp: 800°C

7.3.4.4 Others

7.3.5 Historic and Forecasted Market Size By By Application

7.3.5.1 Household Electrical Appliances

7.3.5.2 Fluid Transportation Piping’s

7.3.5.3 Chemical Industry

7.3.5.4 Auto Industry

7.3.5.5 Metallurgy

7.3.5.6 Others

7.3.6 Historic and Forecast Market Size by Country

7.3.6.1 Russia

7.3.6.2 Bulgaria

7.3.6.3 The Czech Republic

7.3.6.4 Hungary

7.3.6.5 Poland

7.3.6.6 Romania

7.3.6.7 Rest of Eastern Europe

7.4. Western Europe Basalt Fiber Sleeve Market

7.4.1 Key Market Trends, Growth Factors and Opportunities

7.4.2 Top Key Companies

7.4.3 Historic and Forecasted Market Size by Segments

7.4.4 Historic and Forecasted Market Size By By Type

7.4.4.1 Maximum Continuous Temp: 649°C

7.4.4.2 Maximum Continuous Temp: 700°C

7.4.4.3 Maximum Continuous Temp: 800°C

7.4.4.4 Others

7.4.5 Historic and Forecasted Market Size By By Application

7.4.5.1 Household Electrical Appliances

7.4.5.2 Fluid Transportation Piping’s

7.4.5.3 Chemical Industry

7.4.5.4 Auto Industry

7.4.5.5 Metallurgy

7.4.5.6 Others

7.4.6 Historic and Forecast Market Size by Country

7.4.6.1 Germany

7.4.6.2 UK

7.4.6.3 France

7.4.6.4 The Netherlands

7.4.6.5 Italy

7.4.6.6 Spain

7.4.6.7 Rest of Western Europe

7.5. Asia Pacific Basalt Fiber Sleeve Market

7.5.1 Key Market Trends, Growth Factors and Opportunities

7.5.2 Top Key Companies

7.5.3 Historic and Forecasted Market Size by Segments

7.5.4 Historic and Forecasted Market Size By By Type

7.5.4.1 Maximum Continuous Temp: 649°C

7.5.4.2 Maximum Continuous Temp: 700°C

7.5.4.3 Maximum Continuous Temp: 800°C

7.5.4.4 Others

7.5.5 Historic and Forecasted Market Size By By Application

7.5.5.1 Household Electrical Appliances

7.5.5.2 Fluid Transportation Piping’s

7.5.5.3 Chemical Industry

7.5.5.4 Auto Industry

7.5.5.5 Metallurgy

7.5.5.6 Others

7.5.6 Historic and Forecast Market Size by Country

7.5.6.1 China

7.5.6.2 India

7.5.6.3 Japan

7.5.6.4 South Korea

7.5.6.5 Malaysia

7.5.6.6 Thailand

7.5.6.7 Vietnam

7.5.6.8 The Philippines

7.5.6.9 Australia

7.5.6.10 New Zealand

7.5.6.11 Rest of APAC

7.6. Middle East & Africa Basalt Fiber Sleeve Market

7.6.1 Key Market Trends, Growth Factors and Opportunities

7.6.2 Top Key Companies

7.6.3 Historic and Forecasted Market Size by Segments

7.6.4 Historic and Forecasted Market Size By By Type

7.6.4.1 Maximum Continuous Temp: 649°C

7.6.4.2 Maximum Continuous Temp: 700°C

7.6.4.3 Maximum Continuous Temp: 800°C

7.6.4.4 Others

7.6.5 Historic and Forecasted Market Size By By Application

7.6.5.1 Household Electrical Appliances

7.6.5.2 Fluid Transportation Piping’s

7.6.5.3 Chemical Industry

7.6.5.4 Auto Industry

7.6.5.5 Metallurgy

7.6.5.6 Others

7.6.6 Historic and Forecast Market Size by Country

7.6.6.1 Turkiye

7.6.6.2 Bahrain

7.6.6.3 Kuwait

7.6.6.4 Saudi Arabia

7.6.6.5 Qatar

7.6.6.6 UAE

7.6.6.7 Israel

7.6.6.8 South Africa

7.7. South America Basalt Fiber Sleeve Market

7.7.1 Key Market Trends, Growth Factors and Opportunities

7.7.2 Top Key Companies

7.7.3 Historic and Forecasted Market Size by Segments

7.7.4 Historic and Forecasted Market Size By By Type

7.7.4.1 Maximum Continuous Temp: 649°C

7.7.4.2 Maximum Continuous Temp: 700°C

7.7.4.3 Maximum Continuous Temp: 800°C

7.7.4.4 Others

7.7.5 Historic and Forecasted Market Size By By Application

7.7.5.1 Household Electrical Appliances

7.7.5.2 Fluid Transportation Piping’s

7.7.5.3 Chemical Industry

7.7.5.4 Auto Industry

7.7.5.5 Metallurgy

7.7.5.6 Others

7.7.6 Historic and Forecast Market Size by Country

7.7.6.1 Brazil

7.7.6.2 Argentina

7.7.6.3 Rest of SA

Chapter 8 Analyst Viewpoint and Conclusion

8.1 Recommendations and Concluding Analysis

8.2 Potential Market Strategies

Chapter 9 Research Methodology

9.1 Research Process

9.2 Primary Research

9.3 Secondary Research

|

Global Basalt Fiber Sleeve Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 276.34 Mn. |

|

Forecast Period 2024-32 CAGR: |

12.56% |

Market Size in 2032: |

USD 801.49 Mn . |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Frequently Asked Questions :

The forecast period in the market research report is 2024–2032.

Refractory Specialties (USA), Morgan Advanced Materials (USA), HarbisonWalker International (USA), Pyrotek (USA), Owens Corning (USA), Unifrax (USA), Harwick Group (USA), Thermal Ceramics (USA), Guardian Industries (USA), JCP Minerals (USA),3M (USA), BASF SE (Germany), Knauf Insulation (Germany), Schundler Group (Germany), Technobasalt Invest (Ukraine), Imerys (France), Favier Group (France), Saint-Gobain (France), Rockwool (Denmark), Aerospace Tuoxin (China), Jiangsu Tianlong (China), Toray Industries (Japan), Basalt Fiber India (India), Lotte Chemical (South Korea), and other Major Players

The Basalt Fiber Sleeve Market is segmented into Type, Application, and region. By Type, the market is categorized into Maximum Continuous Temp: 649°C, Maximum Continuous Temp: 700°C, Maximum Continuous Temp: 800°C, and Others. By Application, the market is categorized into Household Electrical Appliances, Fluid Transportation Piping’s, Chemical Industry, Auto Industry, Metallurgy and Others. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

A basalt fiber sleeve is a tubular structure crafted from basalt fibers, extracted from natural volcanic rock. These fibers, created by melting basalt at high temperatures and extruding the material, boast remarkable strength, heat resistance, durability, and corrosion resilience. Basalt fiber sleeves are versatile components prized for their multifunctional roles in various industries. They excel in diverse applications owing to their exceptional characteristics. Functioning as high-performance solutions, these sleeves address specific industry needs.

Basalt Fiber Sleeve Market Size Was Valued at USD 276.34 Million in 2023 and is Projected to Reach USD 801.49 Million by 2032, Growing at a CAGR of 12.56% From 2024-2032.