Condition Monitoring Device Market Synopsis:

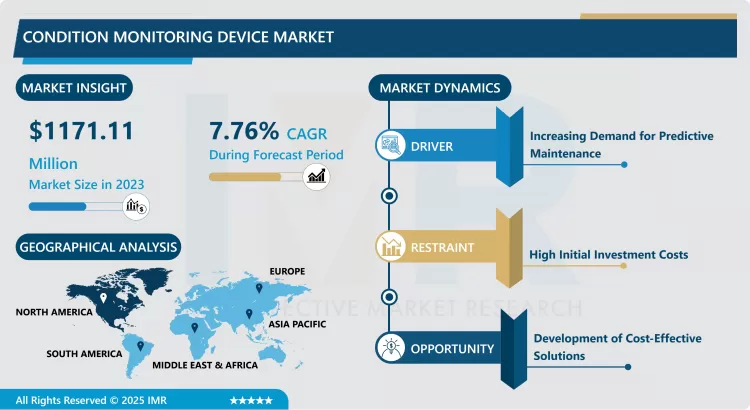

Condition Monitoring Device Market Size Was Valued at USD 1171.11 Million in 2023, and is Projected to Reach USD 2294.65 Million by 2032, Growing at a CAGR of 7.76% From 2024-2032.

The Condition Monitoring Device Market is concerned with the segment of goods and services industry that is involved with creating products to track the condition and performance of mechanical assets used in key industries as manufacturing, energy, transport, and even medical. These tools apply various sensors and analysis method and record data with reference to parameters like vibration, temperature, pressure, audio signals etc and help the organizations to identify trends like failure of equipment before it happens. Since it helps to achieve preventive maintenance and minimizes interruptions for repair work or replacements, condition monitoring devices increase performance, durability, and productivity of assets. Telecom Expense Management (TEM) market trends include the increasing demand for real-time data processing, Industry 4.0 implementations, and trends in predictive maintenance investment.

The condition monitoring device market has been growing at a fast pace in the last couple of years, owing to the need for efficient methodologies like predictive maintenance in a diversified range of sectors. These devices are very useful in providing status information on the health of the machines and equipment which enable businesses to plan for the next failure. Condition monitoring devices use technologies like vibration analysis, thermal imaging and ultrasound testing, to offer real-time information on the statuses of equipment to increase its reliability and safety. The market has been driven more recently by the onset of Industry 4.0 and IoT as more organisations adopt smart technologies in their operations of facilities using monitoring and data analysis from remote locations.

Regionally, North America leads the condition monitoring device market because of the existence of strong manufacturing industries and legislation calling for safety and reliability of equipment. Nevertheless, the Asia-Pacific region is anticipated to post the highest growth rate in the future several years owing to increased industrialization, greater emphasis on infrastructural investment and improvements in operational efficiency. Manufacturing industry, oil and gas, power generation, and transport sector are the most successful industries by using condition monitoring devices. As more firms in the manufacturing industry come to value the potential of condition monitoring in reducing maintenance prices and enhancing production, the market is projected to grow even larger.

The condition monitoring device market evolves based on the general progress of technology. More development and innovation in artificially intelligent and machinable learning algorithm techniques are making it easier to come up with better techniques in data analysis as well as the concept of smart maintenance. This trend is expected to improve the prospects of condition monitoring devices by allowing the devices to give specific outcomes of equipment failures and maintenance. At the same time, the increased demand for making industries and processes sustainable and energy efficient drives the condition monitoring solutions market to embrace new technology to minimize waste and energy consumption. In conclusion, the condition monitoring device market is in an excellent location to experience high growth as technology and need for operational efficiency intensify across industries.

Condition Monitoring Device Market Trend Analysis

Revolutionizing the Condition Monitoring Device Market

- The future advancement of the condition monitoring device market lies into the amalgamation of Internet of Things (IoT) and Industry 4.0 ideas due to which smart condition monitoring devices offer extensive real-time data and analysis results for equipment health. The above advanced monitoring solutions are self-possessed of making observations of fundamental standards such as temperature, vibration, and pressure that are central to the evaluation of the performance of machinery. Since the conditions likely to cause equipment malfunctions are detected early these devices are crucial in minimizing equipment breakdowns and the resultant down time. Companies in this industry including manufacturing, oil and gases, and transportation industries have indeed realized the benefits these technologies provides, not only does it improve the operation of this industries, but it also reduces cost by avoiding any unplanned maintenance.

- The increased operational pressure to achieve operational excellence is likely to increase the use of condition monitoring devices across sectors. This is backed up by regulatory forces and safety requirements that force organizations to upgrade their monitoring solutions. Furthermore, the drive towards sustainability and efficiency of energy is pressuring organizations into looking for technologies that achieve balance and cut costs. Modern standards of wireless communications such as 5G are also improving the effectiveness and the connectivity of condition monitoring systems including remote communication. As a result of the adoption of smart technologies, data, and AI for enhancing the predictive analysis of the device, the global condition monitoring device market is predicted to grow continuously in future based on innovation and adoption.

Growth Opportunities in the Condition Monitoring Device Market

- Since business and industries are emphasizing the improvement of productivity and reducing time loss, the use of condition monitoring technologies is becoming widespread across different industries. By using these devices, firms within sectors like manufacturing, oil and gas, transportation, and energy are keenly monitoring the condition of critical assets. They help organizations design effective interventions that can be applied before major failures occur and cause substantial damages to a company’s operations. Here proactive actions are needed for maintenance and is proving effective for today’s cut throat competition where continuity in operation is much valued.

- Further, while moving from reactive to proactive maintenance not only decreases the expenses on repair work but also enhances the useful life of critical assets, which makes condition monitoring as a critical management focus for organizations. These technologies enable organizations manage their processes such that machines within the production cycles perform effectively as required. Subsequently, this strategic change is also a useful in raising the productivity and profitability of condition monitoring devices as an essential element of the maintenance strategy. Therefore, the significant opportunities are exhibited in this market since industries, allied to digital transformation, will persist seeking solutions that improve reliability.

Condition Monitoring Device Market Segment Analysis:

Condition Monitoring Device Market is Segmented on the basis of Technology, Component, Application, End-Use Industry, and Region

By Technology, Vibration Monitoring segment is expected to dominate the market during the forecast period

- Condition monitoring by vibration analysing is an important aspect in ensuring that the reliability of machinery and equipment is prolonged. This technique harnesses the help of higher stage sensors to acquire info the frequency and amplitude of vibrations which could point out future issues. Some of the problems that can be detected by using vibration measurement include; vibration due to imbalance, vibration due to misalignment and vibration due to bearing failure, which is common in the rotating equipment. The element of constant real-time monitoring these vibrations can really help in assessing the health of a machinery, including indicating problems that, if are left unsolved, will lead to massive concomitant disruptions in operations.

- Enhancing the maintenance strategies within organizations may be enhanced by installation of the best vibration monitoring system. When analyzing vibrations, the maintenance crews can readily discover patterns that show they are linked to future malfunctions, so they can have the parts changed before failure. It not only prevents frequent cases of system breakdown but also lowers costs that are likely to be incurred in emergency repairs and subsidence. As organizations continue to implement predictive maintenance strategies, Vibration analysis and prognosis are among the most important elements that lead to improved efficiency and performance of the assets with a view to increasing their durability.

By End-Use Industry, Manufacturing segment expected to held the largest share

- The manufacturing industry is now investing significantly in the use of predictive maintenance as one of the key ways of ensuring the availability of equipments and improving manufacturing performance. With condition monitoring technologies, the health of those machinery can be determined on a continuous basis and probable failures prevented. This approach eliminates the possibilities of sudden breakdowns, which are very uneconomical to the extent that they can paralyse production lines. Besides the increased demand on the reliability of machines, an additional benefit of the approach is the proper usability of resources whereby models enable the manufacturer to scale down the rates of maintenance and repair work.

- The increased focus on Industry 4. Engineering concepts Cascaded by IoT, AI and extensively used data analytics has fasten the implementation of predictive maintainability in manufacturing. These involve the use of real-time information to build integrated systems, which give feedback across all parameters of a manufacturing equipment. This shift does not only encourages the culture of constant development but also improves decision-makers’ judgments in concerns with maintaining strategies. The higher levels of automation and data orchestration across the architecture of production will require manufacturers to integrate predictive maintenance as key strategies for attaining better productivity and solid operational model.

Condition Monitoring Device Market Regional Insights

North America is Expected to Dominate the Market Over the Forecast period

- The Condition Monitoring Device market in North America has grown at a relatively fast pace in the last few years with critical growth triggers associated with increased investments in smart production technologies such as IoT. North America is the most advanced region where many industries like oil and gas, manufacturing and utility sectors apply condition monitoring systems for improving performance. These industries fully understand that in such businesses downtime and optimum timing for maintenance can often result in significant amounts of loss even when shut down for a short period. Real-time monitoring solutions therefore enable the company to detect signs of eventual equipment breakdown so that preventive action can be taken to minimize sudden equipment breakdown and also enhance equipment longevity.

- In addition, the numerous programs of the government that seek to advance smart manufacturing principles or enhance the facilities have also helped in enhancing the market growth in this area. There are several federal and state initiatives to promote industrial usage of innovative technologies, such as, condition monitoring devices. The need for smart and effective maintenance techniques has emerged as the pressure mounts on organisations to adopt better and sustainable ways of conducting their operations. This trend is backed up by the general perception that condition monitoring is cheaper than having to replace worn out or damaged machinery and this has increased acceptance across all sectors. However, due to technological development and drastic regulatory changes, North American region is expected to dominate the condition monitoring device market in the near future.

Active Key Players in the Condition Monitoring Device Market:

- Emerson Electric Co.

- Honeywell International Inc.

- Siemens AG

- SKF AB

- Rockwell Automation, Inc.

- General Electric (GE)

- National Instruments Corporation (NI)

- Fluke Corporation

- Baker Hughes Company

- Megger Limited

- Other Active Players

|

Condition Monitoring Device Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 1171.11 Million |

|

Forecast Period 2024-32 CAGR: |

7.76% |

Market Size in 2032: |

USD 2294.65 Million |

|

Segments Covered: |

By Technology |

|

|

|

By Component |

|

||

|

By Application |

|

||

|

By End-Use Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Condition Monitoring Device Market by By Technology (2018-2032)

4.1 Condition Monitoring Device Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Vibration Monitoring

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Thermography.

4.5 Ultrasound

4.6 Oil Analysis

4.7 Electrical Monitoring

Chapter 5: Condition Monitoring Device Market by By Component (2018-2032)

5.1 Condition Monitoring Device Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Hardware

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Software

5.5 Services

Chapter 6: Condition Monitoring Device Market by By Application (2018-2032)

6.1 Condition Monitoring Device Market Snapshot and Growth Engine

6.2 Market Overview

6.3 Predictive Maintenance

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

6.3.3 Key Market Trends, Growth Factors, and Opportunities

6.3.4 Geographic Segmentation Analysis

6.4 Asset Management

6.5 Quality Control

Chapter 7: Condition Monitoring Device Market by By End-Use Industry (2018-2032)

7.1 Condition Monitoring Device Market Snapshot and Growth Engine

7.2 Market Overview

7.3 Manufacturing

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

7.3.3 Key Market Trends, Growth Factors, and Opportunities

7.3.4 Geographic Segmentation Analysis

7.4 Oil and Gas

7.5 Energy and Utilities

7.6 Transportation

7.7 Aerospace

Chapter 8: Company Profiles and Competitive Analysis

8.1 Competitive Landscape

8.1.1 Competitive Benchmarking

8.1.2 Condition Monitoring Device Market Share by Manufacturer (2024)

8.1.3 Industry BCG Matrix

8.1.4 Heat Map Analysis

8.1.5 Mergers and Acquisitions

8.2 EMERSON ELECTRIC CO.

8.2.1 Company Overview

8.2.2 Key Executives

8.2.3 Company Snapshot

8.2.4 Role of the Company in the Market

8.2.5 Sustainability and Social Responsibility

8.2.6 Operating Business Segments

8.2.7 Product Portfolio

8.2.8 Business Performance

8.2.9 Key Strategic Moves and Recent Developments

8.2.10 SWOT Analysis

8.3 HONEYWELL INTERNATIONAL INC.

8.4 SIEMENS AG

8.5 SKF AB

8.6 ROCKWELL AUTOMATION INC.

8.7 GENERAL ELECTRIC (GE)

8.8 NATIONAL INSTRUMENTS CORPORATION (NI)

8.9 FLUKE CORPORATION

8.10 BAKER HUGHES COMPANY

8.11 MEGGER LIMITED

8.12 OTHER ACTIVE PLAYERS

Chapter 9: Global Condition Monitoring Device Market By Region

9.1 Overview

9.2. North America Condition Monitoring Device Market

9.2.1 Key Market Trends, Growth Factors and Opportunities

9.2.2 Top Key Companies

9.2.3 Historic and Forecasted Market Size by Segments

9.2.4 Historic and Forecasted Market Size By By Technology

9.2.4.1 Vibration Monitoring

9.2.4.2 Thermography.

9.2.4.3 Ultrasound

9.2.4.4 Oil Analysis

9.2.4.5 Electrical Monitoring

9.2.5 Historic and Forecasted Market Size By By Component

9.2.5.1 Hardware

9.2.5.2 Software

9.2.5.3 Services

9.2.6 Historic and Forecasted Market Size By By Application

9.2.6.1 Predictive Maintenance

9.2.6.2 Asset Management

9.2.6.3 Quality Control

9.2.7 Historic and Forecasted Market Size By By End-Use Industry

9.2.7.1 Manufacturing

9.2.7.2 Oil and Gas

9.2.7.3 Energy and Utilities

9.2.7.4 Transportation

9.2.7.5 Aerospace

9.2.8 Historic and Forecast Market Size by Country

9.2.8.1 US

9.2.8.2 Canada

9.2.8.3 Mexico

9.3. Eastern Europe Condition Monitoring Device Market

9.3.1 Key Market Trends, Growth Factors and Opportunities

9.3.2 Top Key Companies

9.3.3 Historic and Forecasted Market Size by Segments

9.3.4 Historic and Forecasted Market Size By By Technology

9.3.4.1 Vibration Monitoring

9.3.4.2 Thermography.

9.3.4.3 Ultrasound

9.3.4.4 Oil Analysis

9.3.4.5 Electrical Monitoring

9.3.5 Historic and Forecasted Market Size By By Component

9.3.5.1 Hardware

9.3.5.2 Software

9.3.5.3 Services

9.3.6 Historic and Forecasted Market Size By By Application

9.3.6.1 Predictive Maintenance

9.3.6.2 Asset Management

9.3.6.3 Quality Control

9.3.7 Historic and Forecasted Market Size By By End-Use Industry

9.3.7.1 Manufacturing

9.3.7.2 Oil and Gas

9.3.7.3 Energy and Utilities

9.3.7.4 Transportation

9.3.7.5 Aerospace

9.3.8 Historic and Forecast Market Size by Country

9.3.8.1 Russia

9.3.8.2 Bulgaria

9.3.8.3 The Czech Republic

9.3.8.4 Hungary

9.3.8.5 Poland

9.3.8.6 Romania

9.3.8.7 Rest of Eastern Europe

9.4. Western Europe Condition Monitoring Device Market

9.4.1 Key Market Trends, Growth Factors and Opportunities

9.4.2 Top Key Companies

9.4.3 Historic and Forecasted Market Size by Segments

9.4.4 Historic and Forecasted Market Size By By Technology

9.4.4.1 Vibration Monitoring

9.4.4.2 Thermography.

9.4.4.3 Ultrasound

9.4.4.4 Oil Analysis

9.4.4.5 Electrical Monitoring

9.4.5 Historic and Forecasted Market Size By By Component

9.4.5.1 Hardware

9.4.5.2 Software

9.4.5.3 Services

9.4.6 Historic and Forecasted Market Size By By Application

9.4.6.1 Predictive Maintenance

9.4.6.2 Asset Management

9.4.6.3 Quality Control

9.4.7 Historic and Forecasted Market Size By By End-Use Industry

9.4.7.1 Manufacturing

9.4.7.2 Oil and Gas

9.4.7.3 Energy and Utilities

9.4.7.4 Transportation

9.4.7.5 Aerospace

9.4.8 Historic and Forecast Market Size by Country

9.4.8.1 Germany

9.4.8.2 UK

9.4.8.3 France

9.4.8.4 The Netherlands

9.4.8.5 Italy

9.4.8.6 Spain

9.4.8.7 Rest of Western Europe

9.5. Asia Pacific Condition Monitoring Device Market

9.5.1 Key Market Trends, Growth Factors and Opportunities

9.5.2 Top Key Companies

9.5.3 Historic and Forecasted Market Size by Segments

9.5.4 Historic and Forecasted Market Size By By Technology

9.5.4.1 Vibration Monitoring

9.5.4.2 Thermography.

9.5.4.3 Ultrasound

9.5.4.4 Oil Analysis

9.5.4.5 Electrical Monitoring

9.5.5 Historic and Forecasted Market Size By By Component

9.5.5.1 Hardware

9.5.5.2 Software

9.5.5.3 Services

9.5.6 Historic and Forecasted Market Size By By Application

9.5.6.1 Predictive Maintenance

9.5.6.2 Asset Management

9.5.6.3 Quality Control

9.5.7 Historic and Forecasted Market Size By By End-Use Industry

9.5.7.1 Manufacturing

9.5.7.2 Oil and Gas

9.5.7.3 Energy and Utilities

9.5.7.4 Transportation

9.5.7.5 Aerospace

9.5.8 Historic and Forecast Market Size by Country

9.5.8.1 China

9.5.8.2 India

9.5.8.3 Japan

9.5.8.4 South Korea

9.5.8.5 Malaysia

9.5.8.6 Thailand

9.5.8.7 Vietnam

9.5.8.8 The Philippines

9.5.8.9 Australia

9.5.8.10 New Zealand

9.5.8.11 Rest of APAC

9.6. Middle East & Africa Condition Monitoring Device Market

9.6.1 Key Market Trends, Growth Factors and Opportunities

9.6.2 Top Key Companies

9.6.3 Historic and Forecasted Market Size by Segments

9.6.4 Historic and Forecasted Market Size By By Technology

9.6.4.1 Vibration Monitoring

9.6.4.2 Thermography.

9.6.4.3 Ultrasound

9.6.4.4 Oil Analysis

9.6.4.5 Electrical Monitoring

9.6.5 Historic and Forecasted Market Size By By Component

9.6.5.1 Hardware

9.6.5.2 Software

9.6.5.3 Services

9.6.6 Historic and Forecasted Market Size By By Application

9.6.6.1 Predictive Maintenance

9.6.6.2 Asset Management

9.6.6.3 Quality Control

9.6.7 Historic and Forecasted Market Size By By End-Use Industry

9.6.7.1 Manufacturing

9.6.7.2 Oil and Gas

9.6.7.3 Energy and Utilities

9.6.7.4 Transportation

9.6.7.5 Aerospace

9.6.8 Historic and Forecast Market Size by Country

9.6.8.1 Turkiye

9.6.8.2 Bahrain

9.6.8.3 Kuwait

9.6.8.4 Saudi Arabia

9.6.8.5 Qatar

9.6.8.6 UAE

9.6.8.7 Israel

9.6.8.8 South Africa

9.7. South America Condition Monitoring Device Market

9.7.1 Key Market Trends, Growth Factors and Opportunities

9.7.2 Top Key Companies

9.7.3 Historic and Forecasted Market Size by Segments

9.7.4 Historic and Forecasted Market Size By By Technology

9.7.4.1 Vibration Monitoring

9.7.4.2 Thermography.

9.7.4.3 Ultrasound

9.7.4.4 Oil Analysis

9.7.4.5 Electrical Monitoring

9.7.5 Historic and Forecasted Market Size By By Component

9.7.5.1 Hardware

9.7.5.2 Software

9.7.5.3 Services

9.7.6 Historic and Forecasted Market Size By By Application

9.7.6.1 Predictive Maintenance

9.7.6.2 Asset Management

9.7.6.3 Quality Control

9.7.7 Historic and Forecasted Market Size By By End-Use Industry

9.7.7.1 Manufacturing

9.7.7.2 Oil and Gas

9.7.7.3 Energy and Utilities

9.7.7.4 Transportation

9.7.7.5 Aerospace

9.7.8 Historic and Forecast Market Size by Country

9.7.8.1 Brazil

9.7.8.2 Argentina

9.7.8.3 Rest of SA

Chapter 10 Analyst Viewpoint and Conclusion

10.1 Recommendations and Concluding Analysis

10.2 Potential Market Strategies

Chapter 11 Research Methodology

11.1 Research Process

11.2 Primary Research

11.3 Secondary Research

|

Condition Monitoring Device Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 1171.11 Million |

|

Forecast Period 2024-32 CAGR: |

7.76% |

Market Size in 2032: |

USD 2294.65 Million |

|

Segments Covered: |

By Technology |

|

|

|

By Component |

|

||

|

By Application |

|

||

|

By End-Use Industry |

|

||

|

By Region |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Frequently Asked Questions :

The forecast period in the Condition Monitoring Device Market research report is 2024-2032.

Emerson Electric Co., Honeywell International Inc., Siemens AG, SKF AB, Rockwell Automation, Inc., General Electric (GE), National Instruments Corporation (NI), Fluke Corporation, Baker Hughes Company, Megger Limited and Other Active Players.

The Condition Monitoring Device Market is segmented into By Technology, By Component, By Application, By End-Use Industry and region. By Technology, the market is categorized into Vibration Monitoring, Thermography., Ultrasound, Oil Analysis and Electrical Monitoring. By Component, the market is categorized into Hardware, Software and Services. By Application, the market is categorized into Predictive Maintenance, Asset Management and Quality Control. By End-Use, the market is categorized into Manufacturing, Oil and Gas, Energy and Utilities, Transportation and Aerospace. By region, it is analyzed across North America (U.S., Canada, Mexico), Eastern Europe (Russia, Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe), Western Europe (Germany, UK, France, The Netherlands, Italy, Spain, Rest of Western Europe), Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC), Middle East & Africa (Turkiye, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa), South America (Brazil, Argentina, Rest of SA).

The Condition Monitoring Device Market refers to the sector focused on the development and deployment of tools and technologies designed to continuously monitor the health and performance of machinery and equipment in various industries, including manufacturing, energy, transportation, and healthcare. These devices utilize a range of sensors and analytical techniques to collect data on parameters such as vibration, temperature, pressure, and acoustic emissions, enabling organizations to detect anomalies and predict equipment failures before they occur. By facilitating proactive maintenance and reducing downtime, condition monitoring devices enhance operational efficiency, improve asset lifespan, and contribute to overall productivity. The market is driven by the growing need for real-time data analytics, the rise of Industry 4.0, and increasing investments in predictive maintenance strategies.

Condition Monitoring Device Market Size Was Valued at USD 1171.11 Million in 2023, and is Projected to Reach USD 2294.65 Million by 2032, Growing at a CAGR of 7.76% From 2024-2032.