North America Electric Vehicle Adhesives Market Synopsis:

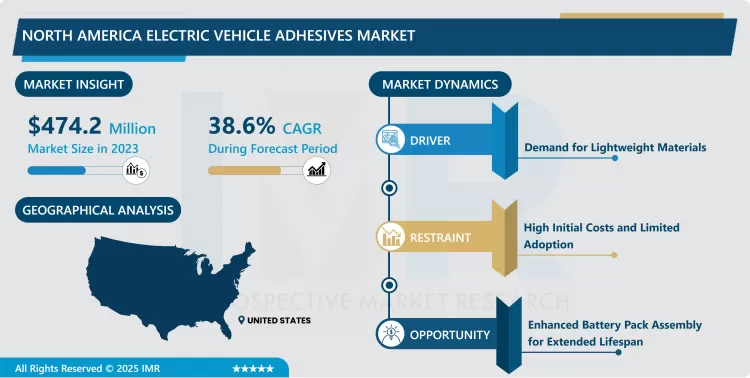

North America Electric Vehicle Adhesives Market Size Was Valued at USD 474.2 Million in 2023, and is Projected to Reach USD 8946.3 Million by 2032, Growing at a CAGR of 38.6% From 2024-2032.

EV Adhesives are an innovative kind of adhesives made to meet the specific needs of electric vehicles (EVs). Adhesives of this category are used in the assembly of various components of EVs, including the batteries, motors, and body panels. They provide high strength, durability, and the ability to withstand heat and chemicals, thus making EV structures maintain its integrity even under extreme conditions. Electric vehicle adhesives are part of light weighting approaches, structural strength improvement, and efficient manufacturing procedures in the rapidly growing EV era.

Strong growth in the EV market has been powered by the increase of EV sales. Such adhesives are used in bonding of battery packs, sealing of components, and the joining of lightweight materials to enhance the EVs performance, durability, and safety.

The increasing adoption of electric vehicles will eventually be accompanied by a greater focus on environmental friendliness, causing manufacturers to strive for sustainable adhesives. Also, the technological evolution of adhesive formulation with excellent thermal conductivity and flame-retardant properties is a vital factor that drives market growth. The electric vehicle adhesives market is set to expand further as a result of concerted efforts to expand EV usage and strict rules demanding cleaner transportation.

The market for electrical vehicle adhesives is also based on changing structure of the automotive industry. Automakers are now spending more on R&D to develop lighter cars that are more energy-efficient, which is making the use of adhesives that can bond dissimilar materials such as composites, aluminium and high-strength steel a must.

The increasing popularity of autonomous and connected vehicles is certainly propelling adhesives that have exceptional qualities in terms of vibrations, shocks, and temperatures, so they remain in optimum condition for a long time.

Together with adhesive producers, automotive OEM are facilitating innovation process and creating specific solutions to different areas of electric vehicles. Hence, electric vehicle adhesives market is a promising area for the manufacturers to explore new avenues beyond the transition towards electric mobility and sustainable transportation.

North America Electric Vehicle Adhesives Market Trend Analysis:

Sustainable Materials Drive Innovation in Electric Vehicle Adhesives

- Sustainable materials are driving the creation of EV (electric vehicle) adhesives that are transforming how the automotive industry assembles cars. In response to the increasing interest in EVs driven by environmental and regulatory issues, manufacturers prioritize sustainability in every stage of the production process. Adhesives play a crucial role in EV assembly as they enhance structural integrity, decrease weight, and boost overall performance. The application of traditional adhesives containing VOCs and other hazardous substances poses risks to health and the environment.

- The introduction of bio-based polymers, resins from plants, and recycled materials offers a more sustainable option. These environmentally friendly options not only lessen the carbon footprint but also guarantee comparable or even better performance than traditional adhesives.

- They align with circular economy principles that emphasize minimizing reliance on scarce resources and preserving resources. By integrating sustainable materials into the adhesive technology of electric vehicles, car manufacturers are not only meeting the demand for eco-friendly transportation but also driving innovation for the advancement of a responsible automotive sector.

Upgraded Battery Pack Assembly Designed for Longer Life Span

- The expanded battery pack design aimed at prolonging the service life of EVs has increased the need for adhesives. As customer awareness of sustainability and efficiency grows, automobile manufacturers are seeking strong and dependable adhesive solutions to improve the performance and longevity of existing advanced battery systems. Adhesives play a crucial role in strengthening battery structure components, protecting them from temperature changes and intense vibrations. As electric vehicle technology progresses, there is a significant demand for adhesives that can withstand the challenges of extended service life while maintaining high safety and efficiency standards.

- The adhesives sector is saturated with innovative formulations designed to endure the rigorous conditions of long-lasting electric vehicle battery pack assembly. These specific adhesives offer better bonding strength, thermal conductivity, and resistance to degradation, thus enhancing the reliability and performance of electric vehicles. As the demand for electric vehicles rises, the adhesive market is poised for significant growth, driven by ongoing innovations in creating new solutions that support the expansion of sustainable transportation technologies.

North America Electric Vehicle Adhesives Market Segment Analysis:

North America Electric Vehicle Adhesives Market is Segmented based on Type, and End-User.

By Type, the Electric Vehicle (BEV) segment is expected to dominate the market during the forecast period

- The growing adoption of BEVs, driven by stringent emission regulations, government incentives, and advancements in battery technology, is fueling the demand for high-performance adhesives. These adhesives play a crucial role in enhancing structural integrity, reducing vehicle weight, and improving crash resistance, making them essential for BEV manufacturing.

- The shift toward lightweight materials and innovative bonding solutions in electric vehicles further accelerates the use of adhesives over traditional mechanical fasteners. With increasing investments in EV production and infrastructure, the BEV segment is projected to witness significant growth, reinforcing its dominance in the North American EV adhesives market.

By Applications, Battery Cell Encapsulation segment is expected to dominate the market during the forecast period

- Encapsulation segment is expected to dominate the market during the forecast period mainly driven by the increasing demand for high-performance adhesives that provide structural integrity and protection to the battery cells. The use of adhesives in encapsulating the battery cells enhances their safety, longevity, and thermal management, which are critical factors for electric vehicle performance.

- As the EV market continues to expand, advancements in adhesive technologies are supporting the growing need for efficient and reliable battery encapsulation solutions. With stricter regulatory standards and a focus on enhancing battery performance, the Battery Cell Encapsulation segment is anticipated to see significant growth, positioning it as a key driver in the overall North America electric vehicle adhesives market.

North America Electric Vehicle Adhesives Market Top Key Players:

- 3M Company (U.S.)

- DuPont (Dow Chemical) (U.S.)

- 3M Company (U.S.)

- Dupont (Dow Chemical) (U.S.)

- Ashland (U.S.)

- Avery Dennison (U.S.)

- Bostik S.A (France)

- Dymax Corporation (U.S.)

- H.B. Fuller (U.S.)

- Illinois Tool Works Corporation (U.S.)

- Lord Corporation (U.S.)

- PPG Industries (U.S.)

- Bostik S.A (France), and Other Active Players

Key Industry Development in the North America Electric Vehicle Adhesives Market:

- In May 2023, Henkel Adhesive Technologies, a leader in automotive adhesives, sealants, and thermal materials, launched its first injectable thermally conductive adhesive, Loctite TLB 9300 APSi, to support the EV battery systems industry. This innovative adhesive provides both structural bonding and thermal conductivity, addressing key challenges faced by OEMs and battery manufacturers in the transition to zero-emission mobility. The launch marks a significant advancement in Henkel's portfolio of solutions for electric vehicles.

|

North America Electric Vehicle Adhesives Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 474.2 Mn |

|

Forecast Period 2024-32 CAGR: |

38.6% |

Market Size in 2032: |

USD 8946.3 Mn |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Country |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter's Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: North America Electric Vehicle Adhesives Market by By Type (2018-2032)

4.1 North America Electric Vehicle Adhesives Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Plug-in Hybrid Electric Vehicle (PHEV)

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Battery Electric Vehicle (BEV)

Chapter 5: North America Electric Vehicle Adhesives Market by By Application (2018-2032)

5.1 North America Electric Vehicle Adhesives Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Pack & Module Bonding

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Thermal Interface Bonding

5.5 Battery Cell Encapsulation

5.6 Other

Chapter 6: Company Profiles and Competitive Analysis

6.1 Competitive Landscape

6.1.1 Competitive Benchmarking

6.1.2 North America Electric Vehicle Adhesives Market Share by Manufacturer (2024)

6.1.3 Industry BCG Matrix

6.1.4 Heat Map Analysis

6.1.5 Mergers and Acquisitions

6.2 3M COMPANY (U.S.)

6.2.1 Company Overview

6.2.2 Key Executives

6.2.3 Company Snapshot

6.2.4 Operating Business Segments

6.2.5 Product Portfolio

6.2.6 Business Performance

6.2.7 Recent News & Development

6.2.8 SWOT Analysis

6.3 DUPONT (DOW CHEMICAL) (U.S.)

6.4 3M COMPANY (U.S.)

6.5 DUPONT (DOW CHEMICAL) (U.S.)

6.6 ASHLAND (U.S.)

6.7 AVERY DENNISON (U.S.)

6.8 BOSTIK S.A (FRANCE)

6.9 DYMAX CORPORATION (U.S.)

6.10 H.B. FULLER (U.S.)

6.11 ILLINOIS TOOL WORKS CORPORATION (U.S.)

6.12 LORD CORPORATION (U.S.)

6.13 PPG INDUSTRIES (U.S.)

6.14 BOSTIK S.A (FRANCE)

6.15 AND

Chapter 7:North America Electric Vehicle Adhesives Market Analysis, Insights and Forecast, 2016-2028

7.1 Market Overview

7.2 Key Market Trends, Growth Factors and Opportunities

7.3 Key Players

7.4 Historic and Forecasted Market Size By By Type

7.4.1 Plug-in Hybrid Electric Vehicle (PHEV)

7.4.2 Battery Electric Vehicle (BEV)

7.5 Historic and Forecasted Market Size By By Application

7.5.1 Pack & Module Bonding

7.5.2 Thermal Interface Bonding

7.5.3 Battery Cell Encapsulation

7.5.4 Other

7.6 Historic and Forecast Market Size by Country

7.6.1 U.S.

7.6.2 Canada

7.6.3 Mexico

Chapter 8 Analyst Viewpoint and Conclusion

8.1 Recommendations and Conclusion

Chapter 9 Our Thematic Research Methodology

9.1 Research Process

9.2 Primary Research

9.3 Secondary Research

|

North America Electric Vehicle Adhesives Market |

|||

|

Base Year: |

2023 |

Forecast Period: |

2024-2032 |

|

Historical Data: |

2017 to 2023 |

Market Size in 2023: |

USD 474.2 Mn |

|

Forecast Period 2024-32 CAGR: |

38.6% |

Market Size in 2032: |

USD 8946.3 Mn |

|

Segments Covered: |

By Type |

|

|

|

By Application |

|

||

|

By Country |

|

||

|

Key Market Drivers: |

|

||

|

Key Market Restraints: |

|

||

|

Key Opportunities: |

|

||

|

Companies Covered in the report: |

|

||

Frequently Asked Questions :

The forecast period in the Cabin Rigid Inflatable Boats Market research report is 2024-2032.

3M Company (US), DuPont (Dow Chemical) (US), 3M Company (US), Dupont (Dow Chemical) (US), Ashland (US), Avery Dennison (US), Bostik S.A (France), Dymax Corporation (US), H.B. Fuller (US), Illinois Tool Works Corporation (US), Lord Corporation (US), PPG Industries (US), Bostik S.A (France), and Other Active Players

The North America Electric Vehicle Adhesives Market is segmented into Type, Application and Region. By Type, the market is categorized into Plug-in Hybrid Electric Vehicle (PHEV), Battery Electric Vehicle (BEV). By Application, the market is categorized into Pack & Module Bonding, Thermal Interface Bonding, Battery Cell Encapsulation, Other. By region, it is analyzed across North America (U.S.; Canada; Mexico)

EV Adhesives are an innovative kind of adhesives made to meet the specific needs of electric vehicles (EVs). Adhesives of this category are used in the assembly of various components of EVs, including the batteries, motors, and body panels. They provide high strength, durability, and the ability to withstand heat and chemicals, thus making EV structures maintain its integrity even under extreme conditions. Electric vehicle adhesives are part of lightweighting approaches, structural strength improvement, and efficient manufacturing procedures in the rapidly growing EV era.

North America Electric Vehicle Adhesives Market Size Was Valued at USD 474.2 Million in 2023, and is Projected to Reach USD 8946.3 Million by 2032, Growing at a CAGR of 38.6% From 2024-2032.